Inconel 600

Key Features:

- Inconel 600 offers superb resistance to caustic or alkali corrosion

- Prevents Stress corrosion cracking

- Free from aging, saltwater & organic acid attack

- Heat and Carburization Resistance

About Inconel 600

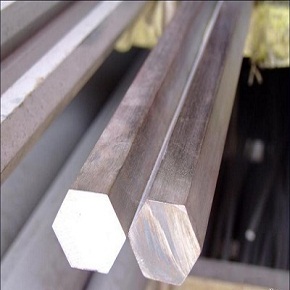

Inconel 600 is a nickel-chromium alloy known for its high-temperature strength, oxidation resistance, and corrosion resistance. It is one of the most widely used Inconel alloys due to its versatility in extreme environments. It is available in the form of Wire, Bar, Strip/Tapes.

Inconel 600 Industrial Nomenclatures: Werkstoff Nr. 2.4816, Inconel 600, Nickelvac 600, Ferrochronin 600, Inco 600, Nickel 600, UNS N06600

🔥 Key Properties

- High-Temperature Resistance

– Retains strength up to 1,100°C (2,012°F).

– Excellent oxidation resistance in continuous high-temperature service.

- Corrosion Resistance

– Resists chloride stress-corrosion cracking.

– Good performance in organic and inorganic acids, alkaline solutions, and water.

- Mechanical Properties

– Tensile Strength: 550–760 MPa (~80–110 ksi)

– Yield Strength: 240–410 MPa (~35–60 ksi)

– Elongation: 40–55% (ductile even at high temps)

- Fabrication & Weldability

– Weldable using TIG, MIG, and resistance welding.

– Work hardens during machining (requires slow speeds and sharp tools).

🚀 Applications

Inconel 600 is used in industries requiring heat and corrosion resistance:

🔧 Industrial & Chemical Processing

– Heat exchanger tubing

– Chemical reactors

– Furnace components (radiant tubes, muffles)

✈️ Aerospace & Gas Turbines

– Combustion cans

– Turbine seals

– Exhaust systems

⚡ Nuclear & Power Generation

– Steam generator tubing (pressurized water reactors)

– Control rod components

🛢️ Oil & Gas

– Downhole equipment

– Flare stacks

Comparison with Similar Alloys

| Property | Inconel 600 | Inconel 601 | Inconel 625 |

| Max Temp. | 1,100°C | 1,250°C | 980°C |

| Oxidation Resistance | Good | Excellent (Al-added) | Very Good |

| Corrosion Resistance | Moderate | Moderate | Excellent (Mo-added) |

| Primary Use | General-purpose | Extreme oxidation | Marine/chemical |

✅ Best for:

– General high-temp oxidation resistance (better than stainless steel).

– Cost-effective compared to higher-nickel alloys like 625.

❌ Limitations:

– Not as strong as 718 or X-750 (not age-hardenable).

– Lower corrosion resistance than 625 (no molybdenum).

⚙️ Machining & Welding Tips

🔧 Machining

– Work hardening is a challenge → Use slow speeds, high feed rates, sharp carbide tools.

– Coolant is essential to prevent overheating.

⚡ Welding

– Recommended methods: TIG, MIG, resistance welding.

– Preheat & Post-Weld Heat Treatment (PWHT) may be needed for thick sections.

📌 Conclusion

Inconel 600 is a versatile, cost-effective nickel alloy for high-temperature and corrosive environments. While it lacks the extreme strength of 718 or corrosion resistance of 625, it remains a reliable choice for furnace, aerospace, and nuclear applications.

+1 206 890 7337

+1 206 890 7337 sales2@super-metals.com

sales2@super-metals.com

Inconel Wire

Inconel Wire  Inconel 617

Inconel 617  Inconel 718

Inconel 718  Inconel 601

Inconel 601  Inconel 625

Inconel 625