Inconel 617

Key Features:

- Inconel 617 is resistant to carburization and spalling

- Elevated temperature high mechanical strength

- Excellent oxidation resistance

- Vey high metallurgical stability

About Inconel 617

Inconel 617 is a solid solution NiCrCoMo alloy offering exclusive blend of high temperature strength and oxidation resistance. Excellent corrosion resistance in a variety of conditions. It can be easily forged and welded by traditional methods.

Availability of high nickel and chromium magnitudes feature alloy 617 with outstanding resistance to oxidation and reduction conditions at the elevated temperatures.

Inconel 617 offers high strength and oxidation resistance up to 1800oF that make it an ideal material for aircraft and land based gas turbines. The alloy has good pitting and crevice corrosion resistance.

Inconel 617 a high temperature nickel alloy is fit for use in the power production units for its creeping resistance and good fabricability properties. It is used in industrial gas turbines and furnaces for its finest working, welding and creeping resistance properties.

Inconel 617 has lower density as compare to tungsten based alloys. It attains exceptionally high metallurgical stability that even after prolong elevated temperature exposure it doesn’t cause formation of embrittling phases.

The presence of nickel, chromium and aluminum elements provides great resistance to carburization at the high temperatures. It can also withstand various aqueous corrosive conditions. At high temperatures, chromium and aluminum result in the development of thin and adherent oxide layer that prevents spalling and offers moderate to good resistance to various reducing and oxidizing acids such as hydrochloric acid, hydrofluoric acid, sulfuric acid and nitric acid.

Industrial Nomenclatures: Inconel 617, Nicrofer 617, In617, UNS N06617

Inconel 617 Specifications: ASME SB-168, AMS 5888, AMS 5889, ASME SB-166, AMS 5887, ASME SB-564, AMS 5887

Why Inconel 617?

Inconel 617 has been proven as a material for furnace retorts for the Tritium Extraction Facility and for high temperature gas cooled reactors. High chromium content accelerates the development of chromium oxide layer that works as a security layer in the aggressive oxidizing conditions. Chromium and molybdenum increase the creep resistance and mechanical strength of alloy.

Alloy 617 has been recommended as a leading metallic material for operations in the nuclear reactors providing long term, secured, explosion resistant and economical use of nuclear energy.

Inconel 617 Applications

Power production units, fossil fuels, nuclear plants, reduction boats in molybdenum refining, catalyst grid supports in nitric acid production, aircraft and land based gas turbines.

Forms Produced

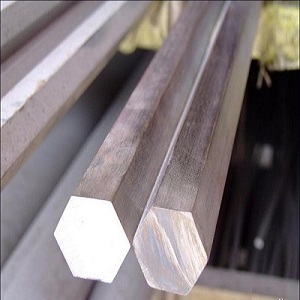

| Inconel Alloy 617 Wire | Inconel Alloy 617 Wire Mesh | Inconel Alloy 617 Strip | Inconel Alloy 617 Sheet |

| Inconel Alloy 617 Rod | Inconel Alloy 617 Pipe | Inconel Alloy 617 Flanges | Inconel 617 Foil |

Heanjia Super-Metals, America offers all above forms of Inconel Alloy 617 in all standard as well as custom specifications.