Kanthal APM Substitute

Key Features:

- Low tendency to ageing and low resistance change

- Long Service Life

- Excellent for high temperature heating, up to 1425°C

- Less creep of electro-thermal components

- Free Sample for Testing

About Kanthal APM Substitute

A Perfect Kanthal APM Wire Substitute–HJ407

1: Kanthal APM Wire Substitute–HJ407’s Development History

Sandvik once established production line in China in 1980s and abandoned it later. How were HJ209 and HJ407 developed as substitutes for Kanthal products? Basing on this production line and over 20 years’ research, we developed HJ209 and HJ407 as a substitute of Kanthal A1 Wire and Kanthal APM Wire. What production technology is used for HJ209 and HJ407? They are produced with the same scientific principle–powder metallurgy.

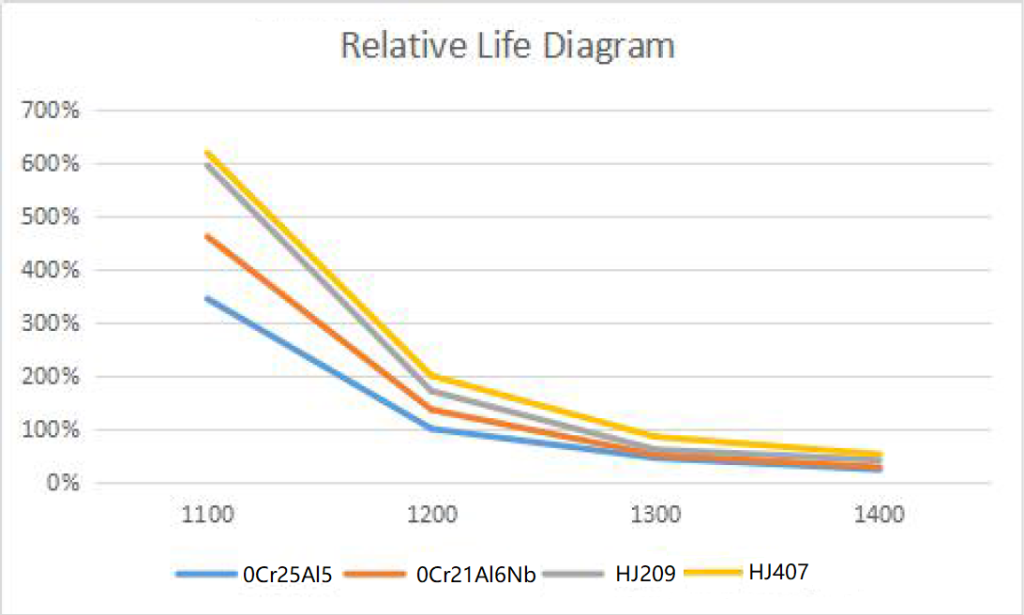

2: Kanthal APM Wire Substitute–HJ407’s High quality and cost effectiveness

The HJ407 Wire’s properties are equivalent to Kanthal APM Wire, but its price is only about $28/KG~$45/KG (Final price depends on product size and ordering quantity). Want cheaper one? The HJ209’s properties are equivalent to Kanthal A1 Wire, and much better than Kanthal D Wire. Its price is only $20/KG~$35/KG. You can use HJ407 as Kanthal APM Wire and Kanthal A1 Wire substitute. Click here for details.

Free sample is available for testing!

Kanthal APM Wire Substitute–HJ407’s Key Features:

1. Low tendency to ageing and low resistance change

2. Small change in resistivity

3. High creep resistance

4. Excellent surface oxidization properties

5. Excellent for high temperature heating, up to 1425°C

HJ407 Wire takes refined master alloy as raw material, uses powder metallurgy technology to manufacture alloy ingots, and is manufactured by special cold and hot processing and heat treatment process. What advantages do I get when using HJ407 Wire in high-temperature environments? The product has the advantages of strong oxidation resistance, good corrosion resistance at high temperature, small creep of electro-thermal components, long service life at high temperature and small change of resistance. In what working environments can I use HJ407 Wire safely and effectively? HJ407 Wire is suitable for high temperature application (max1425 °C), high power density, corrosive atmosphere, carbon atmosphere and other working environments.

HJ407 can be used in ceramic kilns, high temperature heat treatment furnaces, laboratory furnaces, electronic industrial furnaces and diffusion furnaces.

HJ407’s Specifications:

- Round Wire Diameter: Φ0.15 ~ 8.0 mm

- Flat Wire Thickness: 0.1 ~ 0.4 mm Width: 0.5 ~ 4.5 mm

- Flat Strip Thickness: 0.5 ~ 2.5 mm Width: 5 ~ 48 mm

- Coils: can be customized according to customer’s requirements

HJ407’s composition (Wt%):

| C | Si | Mn | Cr | Al | Fe | |

| Min | – | – | – | 20 | 5.5 | Bal |

| Max | 0.04 | 0.5 | 0.4 | 22 | 6.0 | Bal |

HJ407’s Mechanical Properties:

| Tensile Strength at Room Temperature | Elongation rate | Hardness | Tensile Strength at 1000℃ | High Temperature Durability at 1000 ℃and 6MPa |

| 650-750MPa | 15-25% | HV220-260 | 20 MPa | ≥100h |

Density: 7.1g/ cm3

Resistivity: 1.45×10-6 Ω.m

Melting point: 1500℃

Maximum Continuous Working Temperature:1425℃

HJ407 Resistance Temperature Coefficient (Ct):

| Temperature | 700℃ | 900℃ | 1100℃ | 1200℃ | 1300℃ |

| Ct | 1.02 | 1.03 | 1.04 | 1.04 | 1.04 |

HJ407 Average Linear Expansion Coefficient:

| 20-800℃ | 20-1000℃ | 20-1400℃ |

| 14 | 15 | 16 |

HJ407 Fast Life:

| 1300℃ | 1350℃ | |

| Average fast life (Hours) | 110 | 90 |

| Sagging rate after rupture (%) | 8 | 11 |

Note: Tested according to GB/T13300-91 standard

Frequently Asked Question

- What features do Kanthal APM heating alloys offer for high‑temp applications?

Ans. Kanthal APM has Low tendency to ageing and low resistance change, Small change in resistivity, High creep resistance, Excellent surface oxidization properties and Excellent for high temperature heating, up to 1425°C. Heanjia super metals supplies equivalent material HJ407 at much lower cost and faster shipment. - Which powder‑metallurgical FeCrAl alloys are used in high heat environments?

Ans. Powder‑metallurgical FeCrAl alloys like Kanthal APM, HJ209 and HJ407 are used in high temperature furnaces. The highest working temperature can reach 1425℃. - Which advanced high‑temp resistance alloys can outperform conventional FeCrAl?

Ans. Advanced FeCrAl resistance alloys such as Kanthal APM, HJ209 and HJ407 deliver better properties than conventional FeCrAl alloys. They have small change in resistivity, high creep resistance and excellent surface oxidization properties. They can be use in high temperature heating, up to 1425°C. HJ209 and HJ 407 are available in Heanjia. - What FeCrAl alloys are suitable for extreme heat structural parts?

Ans. FeCrAl alloys including Kanthal APM not suitable for extreme heat structural parts because they will become brittle in high temperatures. - Which industrial powder FeCrAl materials are used at elevated temps?

Ans. Industrial powder FeCrAl materials such as Kanthal APM, HJ209 and HJ407 are chosen for demanding high‑temperature applications. HJ209 and HJ407 offered by Heanjia Super Metals with excellent performance.

+1 206 890 7337

+1 206 890 7337 sales2@super-metals.com

sales2@super-metals.com

Kanthal A1 Substitute

Kanthal A1 Substitute  Kanthal Heating Coil Substitute

Kanthal Heating Coil Substitute