Inconel 600

Key Features:

- Inconel 600 offers superb resistance to caustic or alkali corrosion

- Prevents Stress corrosion cracking

- Free from aging, saltwater & organic acid attack

- Heat and Carburization Resistance

About Inconel 600

Inconel 600 Industrial Nomenclatures: Werkstoff Nr. 2.4816, Inconel 600, Nickelvac 600, Ferrochronin 600, Inco 600, Nickel 600, UNS N06600

Inconel 600 is a typically engineered metallic material that offers outstanding heat, oxidation and corrosion resistance. The highest service temperature of this super alloy goes up to 2000oF and the lowest goes down to the cryogenic limits. Alloy 600 offers excellent resistance to organic and inorganic compounds, chloride ion stress corrosion cracking and reducing and oxidizing conditions.Chromium content in alloy 600 offers resistance to sulfur compounds.

Inconel 600 specialty steel is non-magnetic in nature. It has good mechanical properties at the high and low temperatures.

Nickel based super alloys are the best materials for different industrial applications for offering high temperature strength and excellent corrosion resistance. They have good workability and are extremely resistant to the variety of chemicals hence, are suitable for chemical processing units.

Further Forms: Inconel 600 wire, Inconel 600 bar and Inconel 600 plate.

Inconel 600 wire:

The cold drawn Inconel wire is commonly used in heat treatment fixtures, baskets and trays. In order to ensure that you receive the wires that are fit for your application, we perform the strict quality level tests. Inconel 600 wires are made in flat, square and shaped wire forms.

Other Inconel grades available in wire form are- Inconel alloy 601, Inconel 625 and Inconel 718.

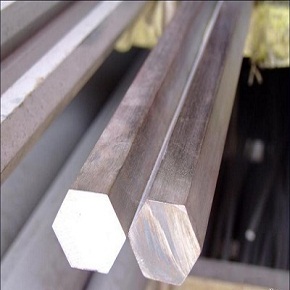

Inconel 600 bar:

Inconel 600 bar is made from the high quality raw materials and is designed as per the international standards. Inconel 600 bars and rods can be formed by different cold and hot working procedures. We produce Inconel 600 bars in diameter 3/16 inch – 40 inch and cutting length 1 – 20ft. There are also other wire grades fabricated in the bar forms such as – Hastelloy Alloy C276 Wire – an extremely versatile corrosion resistant alloy .

Inconel 600 plate:

Our knowledge in Inconel alloy 600 plate specifications needed for each market with great shipping make us a perfect resource for your supply chain requirements. We precisely understand the importance of customization and quality, therefore Heanjia has become the one stop shop for everything in Inconel plate that you need. The plate width can be customized up to 1500mm and length up to 3000mm

Other Inconel grades available in plate form are- Inconel 601, Inconel 625 and Inconel 718.

Inconel 600 Specifications:

| Wire | Sheet | Strip | Rod | Pipe | Fittings |

| ASTM B 166/ASME SB 166, ASTM B 564/ASME SB 564, ASME Code Cases 1827 and N-253, SAE/AMS 5665 and 5687BS 3075NA14, 3076NA14, DIN 17752, 17753, 17754, ISO 97239724, 9725, MIL-DTL-23229QQ-W-390 | ASTM B 168/ASME SB 168, ASTM B 906/ASME SB 906, ASME Code Cases 1827 and N-253SAE/AMS 5540BS 3072NA14, 3073NA14, DIN 17750, ISO 6208, EN 10095, MIL-DTL-23228 | ASTM B 168/ASME SB 168, ASTM B 906/ASME SB 906, ASME Code Cases 1827 and N-253, SAE/AMS 5540, BS 3072NA14 and 3073NA14, DIN 17750ISO 6208EN 10095, MIL-DTL-23228 | ASTM B 166/ASME SB 166, ASTM B 564/ASME SB 564, ASME Code Cases 1827 and N-253SAE/AMS 5665, 5687BS 3075NA14, 3076NA14, DIN 17752, 17753 and 17754ISO 97239724, and 9725MIL-DTL-23229QQ-W-390 | ASTM B 167/ASME SB 167, ASTM B 163/ASME SB 163, ASTM B 516/ASME SB 516, ASTM B 517/ASME SB 517, ASTM B 751/ASME SB 751, ASTM B 775/ASME SB 775, ASTM B 829/ASME SB 829, ASME Code Cases 1827N-20, N-253, and N-576SAE/AMS 5580, DIN 17751, ISO 6207, MIL-DTL-23227 | ASTM B366 |

Inconel 600 Applications:

Aircraft piston engines, exhausts liners, seals, Vacuum furnace accessories, titanium dioxide units, heat processing tanks, muffles, trays, ethylene dichloride crackers, gasoline stabilizer, MgCl2 evaporates, phenol condensers, soap production, superheating devices, steam generator, paper mill and alkaline digesters, high performance sports cars and in manufacturing nuclear reactors.

Heat Processing:

Alloy 600 can be hardened only through cold processing. It is heated up to 1800oF or 982oC for 10 to 15 minutes. Above this limit, even small heating up to 1900oF causes full softening without unnecessary grain development. Because the cooling rate doesn’t influence its softening, the metal can be cooled down by using water or air.

Hot working or Forging:

Nominal sulfur containing furnace conditions should be applied for forging of Alloy 600. Major hot processing is performed from 1850oF to 2300oF, whilst small processing continues up to 1600oF. Hot processing should not be done between 1200oF to 1600oF because of low ductility of metal in this temperature limit.

Inconel 600 Machining:

Alloy 600 can be easily machined in hot processed and annealed forms. Due to production of large amount of heat while machining, it needs high pace steel and cast non-ferrous sharp apparatus. Excellent and efficient results are received by using CVD (chemical vapor deposition) coated carbide tools. It avoids cratering and wear. A small cutting speed where construction occurs, PVD coatings are common. As of its outstanding ductility, alloy 600 produces long and stringy chips. A suitable selection of chip breaker is essential for Inconel 600. If sulfur containing oil lubricants are used, these should be removed completely prior subjecting the metal to high temperature process conditions such as welding.

Cold Processing:

Inconel 600 is cold processed at temperatures below 649oC or 1200oF

Inconel Alloy 600 Welding:

Inconel 600 is fit for ordinary welding, brazing and soldering. Inconel welding electrode 182 for shielded metal arc welding, filler metal 82 for gas tungsten arc and gas metal arc welding, Inconel filler metal 82 and Inco flux 4 submerged arc flux for the submerged arc procedure are preferred.

Forms Produced:

| Inconel Alloy 600 Wire | Inconel Alloy 600 Wire Mesh |

| Inconel Alloy 600 Strip | Inconel Alloy 600 Plate & Sheet |

| Inconel Alloy 600 Rod | Inconel Alloy 600 Pipe |

| Inconel Alloy 600 Flanges | Inconel Alloy 600 Foil |

Heanjia Super-Metals, America offers all above forms of Inconel Alloy 600 in all standard with custom specifications along with more relevant products like Inconel 625 which prevent pitting & crevice corrosion and scc