Performance of Hastelloy grade C276 in chemical and seawater conditions

Hastelloy grades are wrought nickel-chromium-molybdenum alloys which are widely known for their supreme performance in chemical process and related industries. They are ductile, easy to form and weld and have outstanding resistance to stress corrosion cracking in chloride containing solutions. Due to high chromium and molybdenum concentrations, Hastelloy grades can withstand oxidizing and non-oxidizing acids and attains and excellent resistance to pitting and crevice attack in the presence of chlorides and other halides. Additionally, they are highly resistant to sulfide stress cracking and stress corrosion cracking in sour, oilfield conditions.

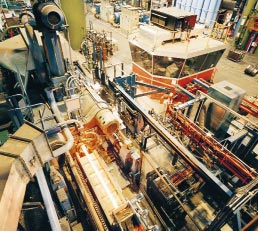

Production of Hastelloy C276 wire in varied specifications is offered by Heanjia for use in reactors, heat exchangers and columns. To evaluate the functionality of Hastelloy C276 in comparison to other materials, it is used to plot 0.1mm/y lines. Performance of C276 grade is compared with SS 316 and Inconel 625, in hydrochloric and sulfuric acid. In hydrochloric acid when concentrations are above 5%, Hastelloy C276 offers widely improved performance as compare to stainless steels and offers higher resistance to large concentrations of both acids than Inconel 625. The concentration limit of 20% HCl is the azeotrope, above which high temperature corrosion tests are not quite feasible.

Hastelloy C276 offers excellent performance in chloride induced pitting and crevice corrosion, these types of attack usually widely affect austenitic stainless steels. To evaluate the performance of alloys against pitting and crevice, it is required to evaluate their Critical pitting and crevice temperatures in acidic 6% ferric chloride, as per the procedures stated in ASTM standard G48. These values refer the minimum temperatures at which pitting and crevice corrosion occur in this solutions within 72 hours,

Other chloride containing conditions, Green death and yellow death solutions are used to evaluate the resistance of different alloys to pitting and crevice corrosion. For Green death, the minimum temperature at which pitting occurred in Hastelloy C276 is the boiling temperature. For Yellow death, Hastelloy C276 prevents pitting in fact also at the highest test temperature of 150oC. The critical crevice temperature of C276 grade in yellow death is 60oC.

One of the major factors of nickel alloys is their resistance to chloride based stress corrosion cracking. A popular solution for evaluating the resistance of materials to this vigorous form of corrosion is boiling 45% MgCl2, usually with stresses U bend samples. As found from the outcomes, Hastelloy C276 and Inconel 625 offer higher corrosion resistance than the comparative, austenitic stainless steels. The tests stopped after 1008 hours.

Performance in sea water

Seawater is usually the popularly used aqueous salt solution. Not usually is it occurred in marine transportation and offshore oil rigs, however it is used as a coolant in coastal facilities. Crevice tests were conducted in still and running seawater at 29oC.

Additionally, Hastelloy C276 also offers great performance in inorganic acid solutions even after welding. Although usually non-uniform nature of weld microstructures causes to accelerated corrosion rate.

While cold processing does not usually affect the resistance of Hastelloy C276 to general corrosion, chloride based pitting and crevice, its scc resistance may be influenced. So, you should contact Heanjia to know when to use Hastelloy grades to receive the best performance.