Alloy 4750

Key Features:

- Alloy 4750 has high magnetic shielding

- Large initial and maximum permeability

- Humidity and corrosion resistance

- Great saturation flux density

About Alloy 4750

Alloy 4750 is a shielding alloy with high initial permeability, maximum permeability and small core losses. It is a nickel-iron alloy with the maximum saturation flux density. It is a versatile material that can be utilized in the various applications like instrument transformers and magnetic shields. High Perm 49 offers suitable resistance to natural corrosion and moisture. It is commonly employed in aircraft and aerospace industry. Good magnetic and electrical properties.

Alloy 4750 is annealed in dry hydrogen conditions up to 2150oF for two to four hours, furnace cooling at 100oF to 200oF per hour to 800oF.

Alloy 4750 Applications

Laminated cores in instrument transformers, magnetic shields, electronic and communication equipments.

Industrial Nomenclatures: High Perm 49, Alloy 4750, Magnifier 50, Carpenter high permeability 49, UNS K94800, K95000, Alloy Steel 4750

Alloy 4750 Specifications

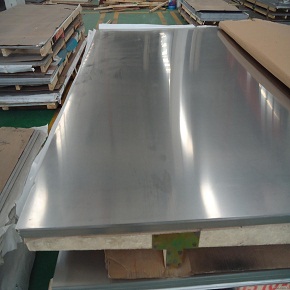

| Wire | Strip | Sheet |

| Mil-N-14411 Comp 3, ASTM A753 | Mil-N-14411 Comp 3 | Mil-N-14411 Comp 3 |

Forms Produced

| Alloy 4750 wire | Alloy 4750 wire mesh | Alloy 4750 strip | Alloy 4750 sheet | Alloy 4750 Foil |

Heanjia Super-Metals, Seattle, USA offers all above forms of Alloy 4750 in all standard and custom specifications.