Monel 400

Key Features:

- Monel 400 offers high strength & strong resistance to chemicals

- Negligible attack in all types of environments

- Excellent corrosion resistance in marine water or salt solutions

- Malleable, ductile and Low CTE

About Monel 400

Industrial Nomenclatures: Nickelvac 400, Nicorros 400, Nickel 400, Specialty Steel, UNS N04400

Monel 400 Wire, Bar and Plate

Monel 400 (Ni 67%) is made of a Nickel-Copper alloy that offers outstanding corrosion resistance in seawater. Monel 400 better withstands oxidation attack as compare to other copper based alloys and significantly prevents attack by sulfuric acid, hydrofluoric acid, hydrochloric acid, nitric acid, hydrofluoric acid and alkalis. It offers outstanding resistance to steam and has good toughness that makes it an ideal material for use in the oil refining industries.

Monel alloy 400 can retain its hardness at the various temperature limits. In annealed condition, monel alloy can be used up to 1000oF or 480oC. It has medium to high strength, fine weldability and exceptional mechanical characteristics at subzero temperatures. Alloy 400 is more economical and superior than Nickel.

Monel 400 is widely produced in the forms-Monel 400 wire, Monel 400 bar and Monel 400 plate.

Monel 400 Wire

Heanjia is a popular supplier of Monel wire for fishing and marine industry. Our Monel wire is known for its tight tolerance, smooth surface and uniformity throughout the length. In order to meet the demands of our potential clients, we offer the Monel wires in various dimensions such as in diameter 0.03 mm – 12 mm and shapes such as flat, square and shaped wires. Monel 400 wire is perfect to withstand internal or external corrosive environments.

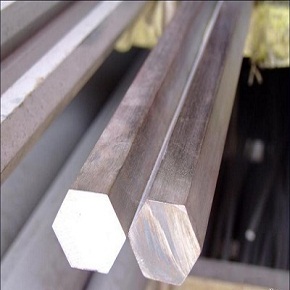

Monel 400 Bar

Becoming a popular firm in the market, Heanjia is engaged in manufacture, supply and export of Monel 400 bars to the worldwide clients at economical price. Monel 400 bars are made available in diameter 3/16 inch – 40 inch and cutting length 1 – 20ft. The bars and rods are custom made in shapes such as Round bar, Square bar and Hexagon bar.

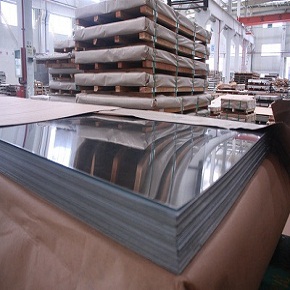

Monel 400 plate

Monel 400 plate finds application in the various industries across the globe. The plates are manufactured in various widhts up to 1500mm and length about 3000mm. Our Monel plates are widely known for their quality and reasonable price. We have a specialized team who confirms the plate quality and standards before its delivery to the potential customers.

Monel 400 Applications

| Marine valves, ship building, propeller shafts |

| Chemical and hydrocarbon treatment apparatus, pumps |

| Crude oil distillation systems, boiler feeder, tanks |

| Electrical and electronic parts |

| Architectural components in institutional buildings |

| It is significant for industries such as marine, oil processing and chemical plants |

| Suitable for fluorine service |

| Used in pickling solutions and oil refining acid sludge |

Monel 400 Specifications:

| Wire | Sheet | Strip | Pipe | Rod |

| BS3075NA13, ASTM B 164, ASME SB 164, ASME SB 564, AECMA PrEN 2305, SAE AMS 4675, SAE, DIN 17752, DIN 17753, VdTÜV 263, QQ-N-28 | SAE AMS 4544, DIN 17750, QQ-N-28 | BS3072NA13, BS3073NA13, ASTM B 127, ASME SB 127, | BS3074NA13, ASTM B 163, ASTM B 165, ASTM B 725, ASTM B 730, ASTM B 751, ASTM B 775, ASTM B 829, ASME SB 163, ASME SB 165, ASME SB 725, ASME SB 730, ASME SB 751, ASME SB 775, ASME SB 829, SAE AMS 4574, DIN 1775, VdTÜV 263 | BS3076NA13, ASTM B 564, AMS 4730, SAE AMS 4731, DIN 17754 |

Monel is a fully safe solution to withstand interior or exterior corrosive environments. It has higher services temperatures as compare to nickel, therefore it is suitable for boiler feed water, heater and heat exchanger applications.

Monel 400 Processing

Hot and cold processing: Alloy 400 is easily hot and cold processed. The temperature limit for hot processing is 1700 – 2150oF and suitable point is 2000oF. Finished fabrications can be made to receive an extensive range of mechanical characteristics by complete monitoring of extent of hot and cold processing and by the selection of suitable methods.

Machining: Monel 400 can be machined at the good rates with the machining tools that are normally used in the industries. The cold drawn or cold drawn stress relieved components are used for the suitable machining and smooth finish.

Welding: The super alloy 400 can be welded by Gas or electric welding methods. Common welding techniques are GMAW, GTAW, SMAW and SAW. The alloy doesn’t require heating prior and after welding. The space around the weld should be clean to avoid contamination of the welded region. Use of argon shielding gas is preferred.

Forms Produced

| Monel Alloy 400 Wire | Monel Alloy 400 Wire Mesh |

| Monel Alloy 400 Strip | Monel Alloy 400 Sheet |

| Monel Alloy 400 Rod | Monel Alloy 400 Pipe |

| Monel Alloy 400 Flanges | Monel Alloy 400 Foil |

Heanjia Super-Metals, America offers all above forms of Monel Alloy 400 in the standard as well as custom specifications