Incoloy 800H/800HT

Key Features:

- Incoloy 800H/HT offers enhanced high temperature creeping resistance

- Higher strength than Incoloy 800 grade

- Stress cracking resistance up to 1100oF

- Great resistance to carburizing, oxidizing and nitriding media.

About Incoloy 800H/800HT

Incoloy Alloy 800H/800HT are a controlled composition alloy, used in applications that need high temperature creeping resistance. They offer good resistance in the variety of acidic and sulfur containing media. The blend of mechanical and thermal processing enables Nickel 800H/HT to tolerate higher stresses than those of traditional alloys.

Alloy 800H is a solution heat processed metallic material with limited carbon content than alloy 800. It offers higher elevated temperature characteristics and has better creeping and stress rupture properties at the temperature limits up to 1100oF – 1800oF or 593oC to 982oC.

The chemistry of Incoloy 800H/800HT provides outstanding resistance to carburization, oxidation and nitridation conditions. They are not susceptible to embrittlement even after prolong operations up to 1200oF to 1600oF. At this temperature range, many stainless steels exhibit brittleness.

Incoloy 800H/800HT Applications

Alloy 800H/HT are commonly used in applications that include high temperature corrosive media such as in Ethylene Pyrolysis, hydrocarbon cracking, furnaces for vinyl chloride diphenol and acetic acid, valves, fittings and other fixtures. They are used in power production, superheater, petrochemical industries, heat processing retorts, muffles jigs, baskets, trays, components, refineries, tubings for oil refining units, electric range heating-element enclosing, ammonia effluent coolers, extruded tubing

Industrial Nomenclatures: Ferrochronin® 800, Nickelvac® 800, Nicrofer® 3220, UNS N08810, N08811

Incoloy 800H/800HT Processing

Nickel-Iron-Chromium alloys can be easily machined by traditional methods. Alloy 800H/HT work harden while machining and keep larger strength. High speed tools are recommended for irregular cuts and soft finish to close tolerance. Use cutting tools with positive rake angles.

Welding: Incoloy 800H/HT offer good weldability similar to grade 800. They are significant for applications that need high creep-rupture strength and ability to be welded with materials that have adequate strength properties at the desired service temperatures. Inconel filter metal 82 is suitable for gas shielded welding for temperatures about 1450oF or 790oC.

Vessel code:

Incoloy 800H is a proven material for the production of boiler and pressure vessels of ASME. The construction of power boilers are stated under Section 1 and for pressure vessels under section VIII, divisions 1 and 2.

Incoloy 800H/800HT Specifications:

| Wire | Pipe | Sheet | Strip | Bar | Fitting |

| ASTM B408, AMS 5766, ISO 9723, ISO 9724, BS 3076NA15, BS 3075NA15, EN 10095, VdTüV 412 & 434, AWS A5.11 ENiCrFe-2, AWS A5.14 ERNiCr-3 | ASTM B 163, ASME SB 163 ASTM B 407/B 829, ASME SB 407/SB 829, ASTM B 514/B 775, ASME SB 514/SB 775, ASTM B 515/B 751, ASME SB 515/SB 751, 1325 and 1983, BS 3074NA15, SEW 470, VdTÜV 412 & 434 ISO 6207, DIN 17459 |

ASTM B409, AMS 5877, BS 3072NA15, BS 3073NA15, VdTüV 412 & 434, DIN 17460, EN 10028-7, EN 10095 | ASTM B 409/B 906, ASME SB 409/SB 906, ASME Code Case 1325, 2339 BS 3072NA15 BS 3073NA15 SEW 470, VdTÜV 412 & 434, DIN 17460, EN 10028-7 & EN 10095 |

ASTM B 408 & ASME SB 408 ASTM B 564 & ASME SB 564 ASME Code Case 1325 ASME Code Case 1949 ISO 9723, 9724, 9725, VdTÜV 412 & 434, DIN 17460 EN 10095 |

ASTM B366 |

Forms Produced

| Incoloy alloy 800H/HT Wire | Incoloy alloy 800H/HT Wire Mesh |

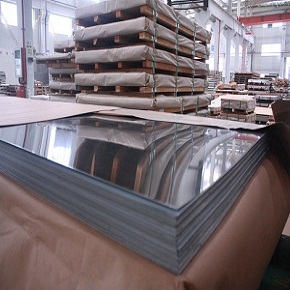

| Incoloy alloy 800H/HT Strip | Incoloy alloy 800H/HT Sheet |

| Incoloy alloy 800H/HT Rod | Incoloy alloy 800H/HT Pipe |

| Incoloy alloy 800H/HT Flanges | Incoloy alloy 800H/HT Foil |

Heanjia Super-Metals, America offers all above forms of Incoloy alloy 800H/HT in all standard as well as custom specifications.