Mechanical behaviour of Inconel alloy 625 welds

A study was conducted to evaluate the microstructural and mechanical properties on the friction stir welded alloy 625. A friction stir welding was performed that resulted into grain refinement. This refinement has an effect on the improvement of mechanical properties of alloy, such as the microhardness and tensile properties were significantly improved of the weld metal as compare to the base alloy.

About Incoloy 625

Alloy 625 has significant applications in aerospace, chemical and marine industries as it offers supreme tensile properties, corrosion resistance and excellent fabricability.

It is a solid solution strengthened alloy containing niobium and molybdenum in its NiCr matrix, the alloy retains its good strength without the need of precipitation heat treatment.

For the development of chemical power plants and its components, welded nickel alloys are widely used. The commonly used welding methods are gas tungsten arc welding and laser welding. However in the fusion welds, because of the development of cast structure, it is hard to obtain excellent physical and chemical properties of the welded area.

But the use of friction stir welding on nickel based alloys has been rarely seen because of their good strength at the high temperatures. Only Inconel Alloy 600 plate is welded by this method although at the slower welding rate, FSW of alloy 625 that possesses greater tensile strength as compare to alloy 600, has not been earlier observed.

Inconel 625 sheet is FSW welded in the presence of argon gas that was used to prevent the surface oxidation of alloy.

Results

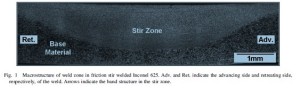

The macrostructure of alloy after friction stir welding is shown below:

The weld entered to a depth about 1.7mm without creating any deformation. The maximum temperature in the plate’s back side was around 800oC that was sufficient to aggregate the grains of alloy. The sample is fine recrystalized during the welding. It is easy to be recrystalized during the hot treatment when compared with the material with higher stack fault energy. So FSW is good for grain refinement in alloy 625.

The enhancement in microhardness is resulted by grain refinement with larger spread of refined grain unlike to in the base alloy. The microhardness in base alloy is 245 to 270 Hv whilst it is 360 – 400 Hv in welded metal. The original alloy has ultimate tensile strength about 943 MPA and extension 58%. On the other hand, the welded sample has ultimate strength about 1019 – 1152 MPa and extension around 34 – 35%.So an increase in mechanical strength is noticed in alloy 625 that was resulted by refined grain in the welded region.

Conclusion

Alloy 625 is a solid solution strengthened alloy because of presence of molybdenum and niobium, it is easily welded with friction stir welding without any deformation. Additionally, this welding method offered grain refinement in alloy 625 attained by an enhancement in the mechanical properties. Moreover, the ultimate tensile strength of welded alloy was better than the nonwelded metal. So Nickel alloy Inconel 625 is found to be more suitable for use in the chemical units and other commercial applications after welded by friction stir procedure.