Inconel 625 Wire- Ideal for high temperature applications

Inconel 625 wire is an alloy of nickel with high resistance to corrosion and oxidation. This alloy is non-magnetic and has high fatigue strength. Inconel 625 alloy has high strength and toughness and can withstand a broad working temperature range (from cryogenic to 2000°F). Inconel 625 has resistance to stress-corrosion cracking due to chloride ions.

Inconel 625 is used in numerous industrial applications including

- Gas turbine engine ducting

- Heat shields

- Chemical plant hardware

- Combustion liners and spray bars

- Furnace hardware

- Special seawater applications

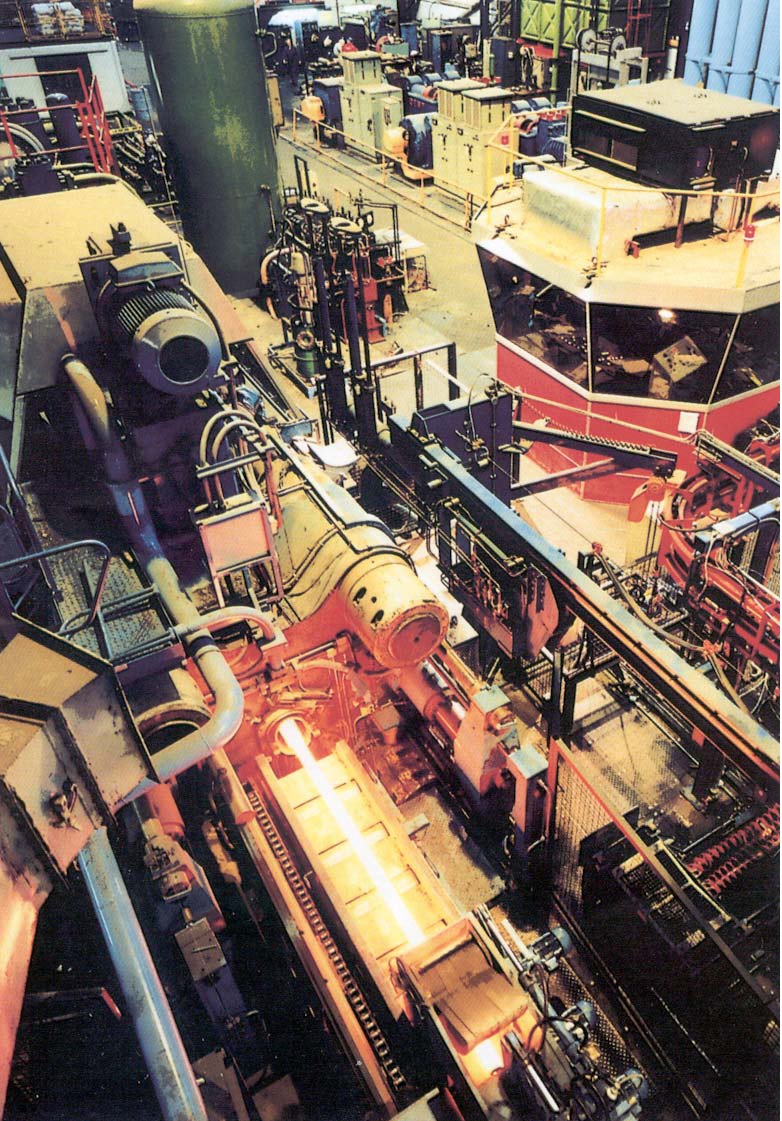

Industrial furnaces and testing furnaces are essential for the development and production of new materials, new ceramics, semiconductors and LCDs. Various general-purpose furnaces are developed including thermo-processing furnaces, magnetic field thermo-processing furnaces, hydrogen gas heating furnaces, continuous ceramic sintering furnaces, vacuum furnaces and other furnaces.

Heating materials are used for a wide variety of applications including domestic heating appliances and industrial furnaces producing very high temperatures. The molten alloy heating element featuring superior durability can sustain a maximum temperature of 1800°C. The heat-resistant products are widely used in Aluminum and other non-ferrous metal dissolution, IC sintering, and other industrial processes. Large-scale electric wave shielded rooms are produced in the field of EMC and other electric wave anechoic chambers, magnetic shielded rooms and shielded rooms for various applications.

Inconel 625 is an alloy of nickel-chromium-molybdenum with resistance to pitting and crevice corrosion. This alloy has excellent resistance properties at elevated temperatures. It can be used at temperatures of up to 1000°C due to its outstanding hot strength and wear properties combined with its high resistance to oxidation and carburization. The solution-annealed finish is used for application temperatures above 600°C. This alloy has a tendency to become brittle in the temperature range between approximately 650°C and 850°C. Inconel 625 wire is used in various forms including rolled and drawn.

Inconel 625 also has its applications in

- Flue gas purification systems

- Offshore engineering plants/equipment

- Plants for the processing of oil and natural gas

- Plants for the processing of phosphoric, hydrofluoric, sulfuric, nitric and hydrochloric acid

- Plants for the processing of organic acids and alkali

Inconel 625 is cold and hot formable. Soft annealing is performed followed by quenching in water to achieve the optimum corrosion resistance for degrees of deformation over 15%. Hot forming is performed in the temperature range between 1175 and 900°C. All workpieces should be freed of grease, oil, paint and other contaminants before heating. A neutral or slightly oxidizing sulfur-free furnace atmosphere needs to be maintained.

Stress-relief annealing is done between temperatures of 600 and 810°C, annealing between temperatures of 900-1050°C and solution annealing is done at temperatures between 1093 and 1200°C. Rapid heat-up is helpful and cooling is done using water, forced inert gas, or forced air. Inconel 625 can be welded using GMAW and GTAW gas metal arc welding processes. The MMA welding processes as joint and build-up welding between like materials can also be used