Corrosion behavior of Inconel 625

Inconel 625 is known for its strength, outstanding fabrication, welding and excellent corrosion resistance properties. Prevention of corrosion of Inconel alloy 625 at the diverse temperatures and corrosive conditions is the basic need for its extensive acceptance in the chemical processing and other applications. This post shows the lab and field data about the resistance of Inconel 625 to the diverse aqueous media causing localized attack, stress corrosion cracking and other kinds of corrosion. The flexibility of alloy for use in oxidizing, carburizing, chlorinated solvents and simulated waste incinerator conditions comprise of halide species are shown.

Preface

Inconel 625, UNS N06625 is fit for use in the various intense attacking conditions. In the nominal conditions, like ambient conditions, fresh and marine water, neutral salts and alkaline media, there is no corrosion. In the variety of aggressive conditions, chromium offers resistance to oxidizing chemicals however high nickel and molybdenum concentration make alloy resistance to nonoxidizing conditions. The concentration of molybdenum makes Inco 625 resistant to pitting and crevice attack. The included niobium content stabilizes alloy against sensitization while welding, hence avoiding immediate intergranular attack. Moreover, high concentration of nickel offers resistance to chloride based stress attack. This pair of corrosion resistance properties makesInconel alloy 625 a commonly used material in the chemical and aerospace sector. This post describes the performance of alloy in two sections as resistance to aqueous and high temperature attack.

Aqueous corrosion

Uniform corrosion:

Uniform corrosion, hence called general corrosion is a type of attack that is often distributed and proceeds at about the same rate over the complete metal surface. The analyses are made to determine the resistance to alloys to uniform corrosion primarily to help in the choice of materials. The tests are normally performed in the different acids to consider various situations. Following table describes the general corrosion resistance of the different alloys including In 625 in the various non-oxidizing and oxidizing acids. Few alloys that are suitably resistant to reducing acids such as Hastelloy B2 may not be fit for use with oxidizing chemicals. Although, In 625 is one of the resistant alloys to uniform attack and may be used in reducing and oxidizing acids.

| Alloy | 40% HCOOH | 10% HCl | 10% H2SO4 | 55% H3PO4 | 85% H3PO4 | 10% HNO3 | 50% H2SO4 + 2.5 % Fe2(SO4)3 |

| SS 304 | 180 mpy | Above 12,000 | 2200 mpy | 400 mpy | 9500 mpy | 1 mpy | 46 mpy |

| SS 316 | 30 mpy | Above 12,000 mpy | 400 mpy | 18 mpy | 450 mpy | 1 mpy | 36 mpy |

| SS 317 | – | 9000 mpy | 360 mpy | – | – | 0.5 mpy | 28 mpy |

| Ni 200 | 10 mpy | 8000 mpy | 130 mpy | 500 mpy | – | Above 12,000 mpy | 8,000 mpy |

| In 600 | 10 mpy | 4400 mpy | 360 mpy | – | 1800 mpy | – | – |

| Incoloy 825 | 8 mpy | 1000 mpy | 18 mpy | 6 mpy | 35 mpy | 0.6 mpy | 11 mpy |

| Hastelloy G-3 | 2 mpy | 1000 mpy | 24 mpy | 5 mpy | 24 mpy | 0.8 mpy | 11 mpy |

| In 625 | 7 mpy | 620 mpy | 44 mpy | 10 mpy | 110 mpy | 1 mpy | 23 mpy |

| Hastelloy C276 | 3 mpy | 220 mpy | 16 mpy | 7 mpy | 18 mpy | 18 mpy | 260 mpy |

| Hastelloy B2 | 0.4 mpy | 7 mpy | 2 mpy | 3.5 mpy | 3.5 mpy | Above 12,000 mpy | – |

Localized corrosion attack

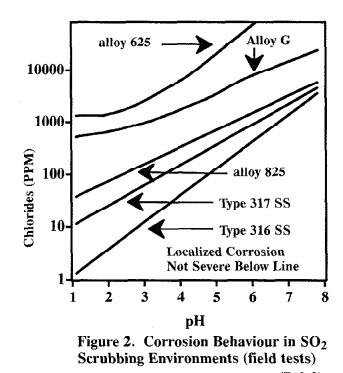

Pitting is a type of localized attack that is limited to a small region instead the entire surface. Pitting and crevice attack or localized attack as related to ppm chloride content and pH of alloys are shown in the following figure:

Chromium and molybdenum have been discovered to be advantageous in enhancing pitting resistance. Inconel 625 has large chromium and molybdenum concentration that accounts for its superior pitting attack. The empirical connection between the critical temperature for pitting to start and chromium and molybdenum and hence rank as first for pitting resistance as shown in above figure.

Chloride stress corrosion cracking

Nickel and nickel base alloys are normally resistant to chloride stress corrosion cracking as compared to stainless steels. The advantageous effect of nickel on limiting the stress corrosion cracking in boiling 42% MgCl2 is observed. The alloys comprising of 42 – 45% nickel will not be attacked in this condition. Inconel 625 consists of 58% nickel, hence it will not be attacked. In the conditions of stress corrosion cracking, Inconel 625 may be attacked by hot water and chlorides, shown in the following table with other conditions that are damaging.

| Heat processing | Conditions in which SCC occurred |

| Annealed | High temperature water, degassed |

| Annealed | Polythionic acid |

| Annealed | Oxygenated water plus lead |

| Annealed | Water, 21 ppm O2 at 316oC |

| Annealed | Steam, cycled between 318 and 385oC ( 605 to 725oF), 10 ppm Cl-, 8 ppm Oxygen |

| Cold processed | 288oC water, 100 ppm O2 |

| Cold processed and aged at 204oC or 400oF | Water, saturated with hydrogen sulfide + 5% NaCl + 0.5% acetic acid + NACE solution at room temperature |

| Cold processed and aged at 500oC or 932oF | Water with 5% NaCl and 0.5% acetic acid at room temperature |

Inconel 625 and different alloys were analyzed in accelerated wet oxidation condition that comprised of a synthetic sewage with chlorides and fluorides, pH 3.2 and a temperature 292oC or 562oF as shown in the following table:

| Alloy | Stress corrosion cracking in liquid phase |

| Hastelloy C-276 | No signs of cracking |

| Inconel 625 | No signs of cracking |

| Hastelloy G | No signs of cracking |

| 26 – 1 | 3/10 in 281 hours |

| 20 – Cb3 | No signs of cracking |

| 20 – Cb3 tube | 1/10 in 440 hours |

| Incoloy 825 | 1/9 in 295 hours |

| Nitronic 50 | 9/10 in 30 hours |

| Nitronic 10 | 8/10 in 16 hours |

| Nitronic 60 | 9/10 in 11 hours |

| Nitronic 33 | 9/10 in 11 hours |

| SS 316 – L | 10/10 in 12 hours |

| SS 304- L | 10/10 in 12 hours |

| SS 316 tube machined and heat treated | 9/9 in 12 hours |

| SS 316 tube machined | 9/9 in 12 hours |

| SS 316 tube | 10/10 in 12 hours |

In 625 and other alloys mentioned containing nickel above 34% are extremely resistant to SCC in this media.

Sulfide stress cracking

Sulfide stress cracking or SSC is an issue in the oil and gas units. It often causes brittle failure of a metal in stress in water mixed with hydrogen sulfide. SSC attack is shown in the following table for various alloys.

| Alloy | Condition | Yield stress | Tensile stress | Hardness, HRc | Threshold stress | |||

| MPa | Ksi | MPa | Ksi | MPa | Ksi | |||

| Titanium | Annealed | 527 MPa | 76.4 ksi | 659 MPa | 95.6 ksi | 20 HRc | 516 MPa | 74.9 ksi |

| MP35N | Cold rolled and annealed | 2005 MPa | 290 ksi | 2046 MPa | 296.8 ksi | 51 HRc | 1965 MPa | 285 ksi |

| Hastelloy C-276 | Cold rolled | 1503 MPa | 218 ksi | 1631 MPa | 236.5 ksi | 41 HRc | 1473 MPa | 213.6 ksi |

| Hastelloy G | Cold rolled | 1496 MPa | 217 ksi | 1617 MPa | 234.5 ksi | 35 HRc | 1470 MPa | 213.2 |

| Monel K-500 | Cold rolled and annealed | 1124 MPa | 163 ksi | 1317 MPa | 191 ksi | 36 HRc | 1101 MPa | 159.7 ksi |

| In 625 | Annealed | 558 MPa | 81 ksi | 979 MPa | 142 ksi | 20 HRc | 546 MPa | 79.2 ksi |

| In 625 | Cold rolled | 1327 MPa | 163 ksi | 1355 MPa | 196.5 ksi | 39 HRc | 1301 MPa | 188.7 ksi |

| In 718 | Solution annealed and aged | 986 MPa | 143 ksi | 1172 MPa | 170 ksi | 34 HRc | 960 MPa | 139.3 ksi |

| In X750 | Solution annealed and aged | 1304 MPa | 150 ksi | 1318 MPa | 191.2 ksi | 37 HRc | 1013 MPa | 147 ksi |

| Nitronic 50 | Cold rolled | 880 MPa | 127.6 ksi | 1076 MPa | 156.1 ksi | 26 HRc | 862 MPa | 125 ksi |

| 3RE60 | Annealed | 591 MPa | 85.7 ksi | 756 MPa | 109.7 ksi | 20 HRc | 532 MPa | 77.1 ksi |

| 17-4 PH | Solution annealed and aged | 858 MPa | 124.5 ksi | 974 MPa | 141.2 ksi | 30 HRc | 86 MPa | 12.5 ksi |

| Custom 450 | Solution annealed and aged | 579 MPa | 84 ksi | 945 MPa | 137 ksi | 25 HRc | 290 MPa | 42 ksi |

The analyses were made at room temperature under constant load in a mixture of oxygen free water comprising of 3000 ppm dissolved H2S, 5% NaCl and 0.5% acetic acid. The threshold stress of Inconel 625 is in close to yield strength in annealed and cold rolled conditions. The threshold stress, although is larger for few alloys in this condition.

Hydrogen embrittlement

An extent of inclination to hydrogen embrittlement was determined as a function of ductility loss. Inconel 625 possesses a moderate ranking as compared to the other alloys. Data made in pressurized gaseous hydrogen is described in the following table:

| Alloy | Hydrogen pressure, ksi | Strength ratio |

| 903 | 5 ksi | 1 |

| AISI 316 | 10 ksi | 1 |

| OFHC Copper | 10 ksi | 1 |

| 6061 T6 | 10 ksi | 1 |

| 802 | 7 ksi | 0.99 |

| 7075 – T73 | 10 ksi | 0.98 |

| Incoloy A 286 | 10 ksi | 0.97 |

| RA 330 | 7 ksi | 0.95 |

| Be-Cu | 10 ksi | 0.93 |

| AISI 310 | 10 ksi | 0.93 |

| AISI 347 | 5 ksi | 0.91 |

| Astroloy | 5 ksi | 0.90 |

| Hastelloy X | 5 ksi | 0.87 |

| FM 718 | 7 ksi | 0.86 |

| AISI 1020 | 10 ksi | 0.79 |

| Ti-6Al-4V | 10 ksi | 0.79 |

| Inconel 625 | 5 ksi | 0.76 |

| AISI 1042 | 10 ksi | 0.75 |

| HY 100 | 10 ksi | 0.73 |

| Monel 400 | 7 ksi | 0.65 |

| MP35N | 10 ksi | 0.50 |

| Inconel 718 | 10 ksi | 0.46 |

| AISI 4140 | 10 ksi | 0.40 |

| Rene 41 | 10 ksi | 0.27 |

| Inconel X-750 | 7 ksi | 0.26 |

| 17-7 PH | 10 ksi | 0.23 |

| AISI 410 | 10 ksi | 0.22 |

| 250 Maraging | 10 ksi | 0.12 |

Intergranular attack

Inconel 625 is stabilized against intergranular corrosion by precipitation of niobium carbides at 927 – 1038oC or 1700 – 1900oF annealing limit. Niobium carbides tie up carbon, making it less available to precipitate as chromium carbides in the grain boundaries. Chromium reduction near the grain boundaries is an effect of intergranular chromium carbide precipitation. This process takes place at specific temperatures and is called as sensitization. Due to sensitization, an alloy becomes vulnerable to integranular corrosion. It can be made inclined to such kind of attack by insufficient annealing processing that would prevent the development of niobium carbides hence making carbon more accessible to precipitate intergranular attack as chromium carbides by subsequent sensitization treatment. At lower annealing temperatures, stabilized niobium carbides are precipitated hence a subsequent sensitizing heat treatment of 704oC- 871oC or 1300oF to 1600oF will cause nominal or no precipitation of chromium carbides at the grain boundaries.

Corrosion in Bleach plant conditions

Pulp and paper bleach plant condition attack analyses have been studied in following table:

Corrosion data in Pulp and paper bleach plant conditions

| Alloy | Total depth pitting (mills) | Alloy | Total depth pitting (mills) |

| Hastelloy G | – | AL-6X | 229 mills |

| Hastelloy G-3 | – | Alloy 28 | 190 mills |

| Inconel 625 | – | T-317X X S/S | 229 mills |

| Hastelloy C276 | – | JS-700 | 247 mills |

| Titanium GR-2 | – | Incoloy 825 | 311 mills |

| Titanium 12 | – | 254 SLX | 414 mills |

| 20Mo-6 | 5 mills | T-317LM S/S | 647 mills |

| AL 29-4 | 7 mills | Nitronic 50 | 658 mills |

| SC-1 | 29 mills | T-317L S/S | 690 mills |

| Schomac 30-2 | 41 mills | 26 – 1 | 770 mills |

| AL-29-4-2 | 102 mills | T 316l S/S | 1158 mills |

Tests in solutions of pH 1.4 – 9.5 with about 5500 pp, chlorides and 80oC or 176oF with power chlorine base oxidizers were made on 38 samples of different materials. It involved 8 chlorination stages,9 chloride dioxide stages and 3 hypochloride stage bleach unit conditions. From the above table, it can be seen that Inconel 625 and other extremely corrosion resistant alloys offer great prevention in bleach plant conditions. High chromium and molybdenum contents of Inconel 625 are responsible for its pitting resistance in this media.

Behavior in Marine water

Different alloys have been ranked by corrosion resistance in marine conditions in the following table. Inconel 625 offers the best resistance in marine media by its high concentration in chromium and molybdenum.

| Alloy | Remarks |

| Most resistant | |

| Hastelloy C | Fully resistant excluding the welds |

| Hastelloy C-276 | Nominal carbon can be welded |

| Inconel 625 | Close to Hastelloy C in overall resistance |

| MP35N | Outstanding performance in preliminary tests |

| Chlorimet – 3 | Cast alloy, outstanding for pumps |

| Rene 41 | Excellent pitting resistance |

| Hastelloy X | Excellent pitting resistance |

| Extremely resistant | |

| F | Often adequate, concentration of molybdenum offers pitting resistance |

| G | |

| Illium R | |

| 700 | |

| Inconel 718 | |

| Resistant, slight pitting | |

| Inconel 600 | Nominal pitting at regions of stagnant marine water |

| Inconel X-750 | |

| Incoloy 800 | |

| Incoloy 825 | |

| Monel 400 | |

| Monel K-500 | |

Inconel 625 is very noble as compare to other alloys. It often acts as cathode when kept in contact with other materials in marine water. Marine water corrosion – fatigue strength for alloy 625 is high. The outcomes of extra corrosion – fatigue analyses on Inconel 625 and other alloys in marine water are described in the following table:

| Alloy | Ultimate tensile strength | Corrosion- fatigue strength at 100 megacycles in marine water | ||

| Ksi | Kgf/mm2 | Ksi | Kgf/mm2 | |

| Inconel – 120 | 205 Ksi | 144 | 70 Ksi | 49.2 |

| Inconel 718 | 189 Ksi | 133 | 60 Ksi | 49.2 |

| Inconel 625 | 149 Ksi | 105 | 50 Ksi | 35.1 |

| Inconel 718 grain size 0.068 | 189 Ksi | 133 | 40 Ksi | 28.2 |

| Inconel 625 | 129 Ksi | 91 | 40 Ksi | 28.2 |

| Inconel 718 grain size 0.152 mm | – | – | 32 Ksi | 22.5 |

| Hastelloy C | 108 Ksi | 76 | 32 Ksi | 22.5 |

| Monel K-500 | 176 Ksi | 124 | 26 Ksi | 18.3 |

| Incoloy 800 | 89 Ksi | 63 | 24 Ksi | 16.9 |

| 18% Ni Maraging steel | 250 Ksi | 176 | 23 Ksi | 16.2 |

| 18% Ni Maraging steel | 250 Ksi | 176 | 15 Ksi | 10.6 |

| Ni-Al Bronze CA 955HT | 115 Ksi | 81 | 15 Ksi | 10.6 |

| AISI SS 304 | 79 Ksi | 56 | 15 Ksi | 10.6 |

| AISI SS 306 | 85 Ksi | 60 | 14 Ksi | 9.8 |

| AISI SS 304L | 75 Ksi | 53 | 14 Ksi | 9.8 |

| AISI SS 316L | 79 Ksi | 56 | 13 Ksi | 9.1 |

| Ni-Al Bronze CA 955 | 87 Ksi | 61 | 12.5 Ksi | 8.8 |

| Mn-Ni-Al Bronze CA 957 | 100 Ksi | 70 | 9 Ksi | 6.3 |

| Mn Bronze CA 865 | 73 Ksi | 51 | 8 Ksi | 5.6 |

| 18% Ni Maraging steel (unsecured) | 250 Ksi | 176 | 5 Ksi | 3.5 |

| Mild steel | 60 Ksi | 42 | 2 Ksi | 1.4 |

Elevated temperature attack

Oxidation test

However alloy 625 is popular for resistance to aqueous attack, it also offers suitable resistance to oxidation and scaling at the elevated temperatures. An oxidation analyses was performed through air plus 5% added water vapor moving at the speed of 500 cc/min at 1000oC or 1832oF for 1008 hours. Water addition through bubbling air by water controlled at 33oC or 91oF to develop 5% water vapor. Regularly the samples were pulled out of the furnace and weighed subsequent to quenching to room temperature to receive a mass variation as a function of time.

A cyclic oxidation analysis was performed on the elevated temperature alloys for example Inconel 601, 617 to determine the scale reliability. In this condition, cyclic oxidation analyses was performed at 982oC or 1800oF in which the samples were heated to temperature for 15 minutes and quenched in air for five minutes. The specimens were weighed subsequent to 100 cycles to receive the mass variation. The outstanding resistance of Inconel 625 to cyclic oxidation describes the potential of alloy to maintain the security oxide coating in the vigorous cyclic condition. Incoloy 800 must be stopped subsequent to 1200 cycles.

Carburization resistance

Development of stable oxide scale on the surface is a base of carburization resistance of a material. An analysis was made to find the relative high temperature carburization resistance of complex alloys utilized in the ethylene furnaces. The analysis involves subjecting alloys to a mixture of hydrogen and 1 – 3% methane at required temperatures. The samples are regularly eradicated for weighing by eradicating them to the cold end of the test chamber and flushed with argon to decrease oxidation. Inconel 625 offers outstanding resistance to carburization at 1000oC in hydrogen gas – 1%Methane at 1000oC for 1000 hours. Mass variation in nominally oxidizing – carburizing condition, H2 – 5.5%CH4-4.5%CO2 at 1000oC or 1832oF for around 1000 hours. Inconel 625 offers comparable resistance to Inconel 600 and superior to alloys 800 and 600 in this condition.

Service of alloy 625 in chlorine based media

Chlorine is a main component in the various industrial process conditions for example mineral chlorination, ethylene dichloride and vinyl chloride monomer development, aluminum smelting and refining, fuel element treatment and heat recovery units. Elevated temperature halide attack has been noticed in fossil fuel boilers, coal gasification unit, gas turbines and in municipal and chemical waste incinerators. Municipal waste consists of 0.5% halides in dry form. Many lab analysis simulating waste incineration conditions have been limited to temperatures varying from 120 – 650oC or 248 – 1202oF. As nickel and nickel base alloys have a prolong reputation for their resistance to halogen attack. It refers to their significance in extending the temperature limit of lab data in simulated HCl conditions. The temperature limit chosen in this analysis is 593 – 927oC or 1100 – 1700oF. This limit is a standard for the flue gas temperature. The boiler interiors and flue stacks can specifically be considered to experience thermal exposure in this temperature limit. The considered condition for this analysis was Nitrogen-10% carbon dioxide-9% oxygen-4%HCl – 130 ppmHBr-100ppm SO2.

The tests were made in a 100mm dia mulllite tube in a horizontal electrical resistance furnace. The test samples were in the form of pins, 7.6 mm dia by 19 mm length. The samples of the whole alloys were subjected to 4% HCl conditions at 593, 704, 816 and 927oC or 1100, 1300, 1500 and 1700oF. The gas composition was developed by combining a gas mixture of nitrogen, sulfur dioxide, carbon dioxide and oxygen with hydrochloric acid and hydrogen bromide gases. The eventual gas chemistry was metered in the mullite tube with electronic flow controllers at an overall rate of 500 cc/min.

The metal loss for alloys analyzed in N2-10%CO2-9%O2-4% HCl- 130 ppm HBr – 100ppm sulfur chlorides at 593, 704, 816 and 927oC or 1100oF, 1300oF, 1500oF and 1700oF for 300 hours is described in following table:

| Alloy | 593oC or 1100oF | 704oC, 1300oF | 816oC, 1500oF | 927oC or 1700oF |

| SS 309 | -2.62 mg/cm2 | -117.89 mg/cm2 | – | -77.70 mg/cm2 |

| SS 316 | -5.48 mg/cm2 | -152.08 mg/cm2 | -32.75 mg/cm2 | 45.74 mg/cm2 |

| SS 347 | -1.61 mg/cm2 | 327.80 mg/cm2 | -221.65 mg/cm2 | -68.36 mg/cm2 |

| In 600 | -0.32 mg/cm2 | -0.98 mg/cm2 | -6.93 mg/cm2 | -10.18 mg/cm2 |

| In 601 | -0.05 mg/cm2 | -2.19 mg/cm2 | -7.24 mg/cm2 | -29.53 mg/cm2 |

| In 617 | -0.51 mg/cm2 | -8.38 mg/cm2 | -10.81 mg/cm2 | -44.64 mg/cm2 |

| In 625 | -0.52 mg/cm2 | -2.06 mg/cm2 | -5.86 mg/cm2 | -5.91 mg/cm2 |

| In 690 | -0.13 mg/cm2 | -1.12 mg/cm2 | -14.27 mg/cm2 | -24.21 mg/cm2 |

| In 800 | -0.53 mg/cm2 | -245.22 mg/cm2 | -6.63 mg/cm2 | -18.98 mg/cm2 |

| In 825 | -1.53 mg/cm2 | -127.34 mg/cm2 | -8.52 mg/cm2 | -25.89 mg/cm2 |

Outline

With high nickel, chromium, niobium and molybdenum concentrations, Inconel 625 offers good aqueous corrosion resistance in the variety of severe conditions. It is resistant to aqueous attack in the various media similar to alloys such as grade C-276.