High Functionality Stainless Steels

The high performance stainless steels are those steel types that are manufactured for providing better corrosion resistance in the severe conditions as compare to traditional steel type 304l that consists of 18 percent chromium (Cr), 8 percent nickel (Ni) and steel type 316l that consists of similar content of Cr and Ni with 2 percent added molybdenum. Their excellence in preventing pitting and stress corrosion cracking is particularly proven in conditions in availability of chloride ion. This functionality is received through large contents of chromium, nickel, molybdenum and nitrogen alloys and developing the steels with small content of carbon to maintain the resistance properties while fabrication as well as welding.

The commercial developments of high functional steel grades introduced with the emerging needs of steel melting and refining techniques made it feasible to cost-effectively create chemistries while including lower carbon content and close composition control. These techniques are vacuum melting, electron beam remelting, electroslag remelting etc and those chosen from the modern commercial perception are vacuum oxygen decarburization (VOD) and argon oxygen decarburization (AOD).

Initialization in 1970s, the stainless steel grades have received wide technical and industrial significance. These are categorized as austenitic, ferritic and duplex stainless steels (austenitic plus ferritic). The steel grades in each group have standard common factors however there is a broad range of corrosion resistance and other properties that determine the suitability of each alloy grade in providing adequate functionality for a specific need. The high nickel austenitic steels are normally recommended for intense acid applications and for providing resistance to chloride induced pitting and crevice corrosion attack. These are commonly used in the flue gas cleaning device dealing with acid condensates, acidic solutions comprising of potential oxidizing media for example in paper bleaching. Considering the significance of fabrication, austenitic stainless steel grades are recommended due to their comparative convenient welding, these steel grades are widely employed in the offshore and nuclear fuel piping that are extensively based on weld feature. If needed a thin sheet, the ferritic steel types prove to be extremely affordable hence they are employed as tubes in the several types of heat exchangers.

The austenitic ferritic Duplex stainless steel grades are commonly chosen when strength is a main factor. These are employed in the pressure vessels in the chemical treatment plants and have a wide service in the heat exchangers.

The family of these stainless steels provides excellent resistance to chloride pitting and stress corrosion cracking better than steel grades 304 and 316, hence the production factors usually describe the eventual steel to be chosen for service in the chloride conditions.

The high functionality stainless steel grades are highly in demand than SS 304 and SS 316 considering the metallurgical and fabrication necessities. It is because of the steel nature and challenging applications.

Austenitic high functional stainless steels

The austenitic series of stainless steels have properties with its standard type counterpart. These types in the annealed conditions offer a single phase, face centered cubic (fcc) austenite and are non-magnetic in nature. This configuration is attributed by comparatively small yield strength, large work hardening rate and large tensile strength, good ductility and formability particularly suitably low temperature hardness and the incapability to be strengthened by heat processing. In addition of corrosion resistance, the prime variation in the comparison with the typical steel types is that the high functional grades quickly produce secondary phases at the elevated temperatures. These phases may be deleterious to specific mechanical characteristics and corrosion resistance and hence the applications of these stainless steels at the temperatures exceeding 500oC or 930oF are confined. Moreover, care should be taken to prevent developing deleterious magnitudes of these phases while elevated temperature processes like forging or welding. The high functionality stainless steels are SS 316l, Incoloy 825, SS 904l.

Austenitic stainless steel grades category A

This category contains the stainless steels basically produced for service in powerful and warm sulfuric acid solutions. These need prevention of corrosion that is provided by large nickel percentage such as Incoloy Alloy 825 grade.

Duplex high functionality stainless steels

The Duplex stainless steel grades are metallurgically produced to attain a microstructure in the annealed condition comprising of almost equal parts of austenitic and ferritic structures. It is obtained by lowering the nickel concentration and increasing the chromium concentration about 22 to 26 percent. The molybdenum percent is kept similar to SS 317l. The duplex steels attain properties that receive benefits of both of these phases. More crucially, these steel types offer extremely high strength with essential ductility and hardness. They offer a great combination of strength, resistance to general corrosion and stress corrosion cracking while becoming cost-effective due to controlled content of nickel. Considering the austenitic family, these types are unhardenable through heat processing. The Duplex steel grades need cautious production processes to prevent damage caused by secondary phases and to sustain the balance of about equal magnitudes of ferrite and austenite. These steel grades offer excellent versatility in manufacturing and corrosion resistance. They offer enhanced corrosion resistance to stress cracking than SS 316. The common grades of this family is duplex stainless steel 2205 that is a significant member of duplex family as it pairs corrosion resistance, easy fabrication and cost effective characteristics.

Physical Metallurgy

Phase relations in iron-chromium-nickel steels

The high functionality stainless steels are excellent understood metallurgically by evaluating iron-chromium-molybdenum ternary system and regarding enhancement introduced by various alloying agents. This ternary system often defines the primary phases such as austenite and ferrite that differentiate the structural family of steel grades. The basic alloying agents added are molybdenum (Mo), Nitrogen (N) and carbon © and in stabilized ferric stainless steels are titanium (Ti) and niobium (Nb). These elements with chromium develop secondary phases which are unwanted. A complete knowledge of conditions and emergences of primary and secondary phases is important for the complete use of high functionality stainless steels.

Sigma phase is a most commonly occurring secondary phase and it usually affects mechanical and corrosion resistance properties of duplex steels. I n the equilibrium conditions, sigma can be produced at the moderate temperature virtually in all grades. Large magnitudes of sigma phase can be produced in the high chromium ferritic and duplex steel types. Due to quicker diffusion rates in ferritic steels than austenitic steels, reaction mechanism accelerates the sigma development in the ferritic compositions. Sigma phase specifically leaves negative impact on the toughness in the ferritic steel grades however it extensively affects the hardness and corrosion properties in austenitic steels.

Alpha prime phase formation is found in iron-chromium alloys containing chromium up to 12% and titanium after extensive exposure to the high temperatures. Alpha prime phase will create quickly in ferrite alloys containing chromium more than 18%. Molybdenum and other alloying agents negatively influence the stability limits and the mechanism of formation of alpha prime and other secondary phases, normally improving their production rate. From the view of the commercial development and application of these stainless steels, efforts are made to sustain a ferritic structure comprising of titanium or niobium carbonitrides only.

The comparative extents of ferrite and austenite phases are generally based on chemistry and thermal treatment of Duplex steels. Nominal variations in chemistry and thermal work can produce wide effects on the relative volume fraction of these phases in the finished mill product or material subsequent to processing like welding. Since ferrite is a basic solidification phase, it is feasible to produce more than same amount of ferrite in the finished mill product subsequent to development however the reverse is not valid in regards to austenite.

Sigma phase is also a firm phase in the high functional duplex stainless steels. The higher temperature point of a sigma phase consistency is slightly more in the duplex types as compare to in the ferritic steels about 900oC or 1652oF. The alpha prime can be precipitated in the duplex grades, producing in the ferrite phase in the identical way as it develops in the completely ferritic alloys. Using nitrogen as a compositional agent in such steels can develop chromium nitrides particularly in case of high magnitude of ferrite.

On the base of chemistry of austenitic stainless steels, these grades can solidify with austenitic phase as the basic dendrites or in a combined form of a ferrite and austenite. Since the austenite grain limits are more sensitive to contamination phenomena as compare to ferrite or austenite – ferrite limits and because the diffusion rates are normally lower in austenite, there can be a significant variation in the hot cracking, warm treatment and separation behavior in the different high functionality austenitic stainless steels on the base of their mode of solidification. The chemistries develop some ferrite at the period of solidification that is less sensitive to the solidification and various hot fracture issues. Similar to in other stainless steel alloys, sigma and other secondary phases become stable at small temperatures. The higher temperature limit of sigma phase firmness in the industrial steel grades is up to 1050oC or 1922 oF, more than in ferritic or duplex grades. The degree to which these phases may occur is based on the actual composition, solidification rate, segregation and thermal mechanical processing. The occurrence of minimum amount of one or few of these phases should be taken into account generally in several commercial austenitic grades.

Secondary Phases

Simple ternary phase diagrams offer a starting point for perceptive complex metallurgy of these multi-component alloys. It is also essential to know which secondary phases can survive and under what conditions, since their incidence can have deep effect on the corrosion resistance and mechanical characteristics. Secondary phases that have been observed in the high functional stainless steels are categorized as carbides, nitrides or intermetallic compounds.

Mechanical Properties

While the chief factor for the production of high functional stainless steels is always been the corrosion resistance. In several times, better mechanical properties have also been received. It is particularly valid for the metllurgically complex duplex stainless steel grades that offer excellent combination of strength and hardness upon controlling their structures. It relates to the nitrogen improved austenitic grades that have outstanding toughness at the strength levels more than standard grades. It is important considering the price, as the thinner regions can usually lower the cost related with the high alloying content. This advantage has been utilized to be beneficial in the product forms to decrease the price of big size pipe vessels, wide production process, pressure vessels, pipes and to decrease the weight of the topside shapes on the offshore plants.

Austenitic stainless steels

The mechanical characteristics of the high functional austenitic grades have outstanding combination of high strength, ductility and hardness over a large temperature limit. They possess significant impact strength at the mild temperatures. These steels have good strength as the strength level increases with improving the alloy content. The essential strength enhancing element in these steel grades is nitrogen that also enhances corrosion resistance and prevents the development of intermetallic phases. However by increasing the nitrogen percentage the strength factor decreases therefore in the commercial steel types, its content is limited to 050% that offers the minimum required yield strength about 420 to 460 MPa or 61 to 67 ksi. While presence of nitrogen and other elements reduce the ductility, grades like SS 316l still manage to retain adequate ductility to deal with the cold forming processing. The list of least mechanical property required for these grades as specified by ASTM standards for forms like strip, sheet and plate is provided following:

| Grade | UNS No. | ASTM | Tensile strength | Yield strength | Elongation | Hardness | |||

| Ksi | Mpa | Ksi | Mpa | % | Brinell | HRB | |||

| SS 316l | S31603 | A 240 | 70 ksi | 486 MPa | 25 ksi | 170 MPa | 40 % | 217 | 96 HRB |

| SS 317l | S31703 | A 240 | 75 ksi | 515 MPa | 30 ksi | 205 MPa | 40 % | 217 | 96 HRB |

| Alloy 20 | N08020 | A 240 / B 463 | 80 ksi | 551 MPa | 35 ksi | 241 MPa | 30 % | 217 | 96 HRB |

| Incoloy 825 | N08825 | B 424 | 85 ksi | 586 MPa | 35 ksi | 241 MPa | 30 % | – | – |

| 317 LN | S31753 | A 240 | 80 ksi | 550 MPa | 35 ksi | 240 MPa | 40 % | 217 | 96 HRB |

| 260 | – | – | 80 ksi | 550 MPa | 40 ksi | 275 MPa | 35 % | 217 | – |

| 317 LM | S31725 | A 240 | 75 ksi | 515 MPa | 30 ksi | 205 MPa | 40 % | 217 | 96 HRB |

| 317 LMN | S31725 | A 240 | 80 ksi | 550 MPa | 35 ksi | 240 MPa | 40 % | 223 | 97 HRB |

| 204X | – | – | 73 ksi | 500 MPa | 30 ksi | 210 MPa | 35 % | 187 | 90 HRB |

| 310 MoLN | S31050 | A 240 | 80 ksi | 550 MPa | 35 ksi | 240 MPa | 30 % | 217 | 96 HRB |

| 700 | N08700 | B 599 | 80 ksi | 550 MPa | 35 ksi | 240 MPa | 30 % | – | 90 |

| SS 904l | N08904 | A 240 / B 625 | 71 ksi | 490 MPa | 31 ksi | 220 MPa | 35 % | – | – |

| 20 Mo-4 | N08024 | B 463 | 80 ksi | 551 MPa | 35 ksi | 241 MPa | 30 % | 217 | 96 |

| 20Mod | N08320 | B 620 | 75 ksi | 517 MPa | 28 ksi | 193 MPa | 35 % | – | 95 |

| Alloy 28 | N08028 | B 709 | 73 ksi | 500 MPa | 31 ksi | 214 MPa | 40 % | – | – |

| 20Mo – 6 | N08026 | B 463 | 80 ksi | 551 MPa | 35 ksi | 251 MPa | 30 % | 217 | 96 HRB |

| 25 – 6Mo | /N08026 N08926 | A 240 / B 625 | 94 ksi | 650 MPa | 43 ksi | 295 MPa | 35 % | – | – |

| 1925 hMo | – | – | 94 ksi | 650 MPa | 43 ksi | 300 MPa | 35 % | 217 | 96 HRB |

| 254N | – | – | 79 ksi | 550 MPa | 37 ksi | 250 MPa | 35 % | – | – |

| SB8 | S31254 | A 240 | 94 ksi | 650 MPa | 44 ksi | 300 MPa | 35 % | 223 | 97 HRB |

| 254 SMO | N08367 | A 240/ B 688 | 100 ksi | 690 MPa | 45 ksi | 310 MPa | 30 % | 240 | – |

| Al-6XYUS 170N | – | – | 100 ksi | 690 MPa | 43 ksi | 300 MPa | 35 % | 217 | 97

HRB |

| 2419 MoN | – | – | 120 ksi | 820 MPa | 67 ksi | 460 MPa | 30 % | – | – |

| 4565S | S34565 | – | 115 ksi | 800 MPa | 61 ksi | 420 MPa | 35 % | – | – |

| 3127 hMo | N08031 | B 625 | 94 ksi | 650 MPa | 40 ksi | 276 MPa | 40 % | – | – |

| 654 SMO | S32654 | A 240 | 109 ksi | 740 MPa | 62 ksi | 425 MPa | 35 % | 250 | – |

The strengthening rate of SS 316l at the mild temperature is not as high as SS 316 and other standard types because of excellent stability of high functional steels. It is a plus point to ductility as well as hardness and in applications where small magnetic permeability is needed. These steel types have great toughness at the room temperature even also those consisting of significant content of nitrogen.

The high functional austenitic steel types also sustain their strength over the wide range of high temperature limits. They can offer considerably better performance to the elevated temperatures as compare to ferritic and duplex grades as they are insensitive to alpha prime embrittlement. It is particularly valid for grades containing low chromium and molybdenum contents or high nickel alloys.

Duplex stainless steels

Duplex steel types offer very high tensile and yield strength properties. Their ductility lies between ferritic and austenitic grades. The strength level improves while ductility lowers with increase in the alloying content such as nitrogen. The essential strength of duplex types is because of the mixed effect of ferrite in increasing the yield strength and that austenite increases high tensile strength from strain toughening.

The high temperature strength of duplex stainless steel types is extremely large. For standard duplex steels types, the design ASME code allowable stress are limited to 315 oC or 600oF due to risk of alpha prime embrittlement. These grades sustain hardness even below to engineering application temperatures but not as low as to cryogenic applications that need fully austenitic structures. While these grades attain a specific transformation temperature, they attain essential hardness at low temperatures about -100oC or – 150oF. Although hardness is not isotropic and is controlled by increasing ferrite percentage. The industrial grades consist of about 40 to 60 percent ferrite in the as produced solution annealed form. The ferrite percentage describes a suitable adjustment between mechanical and corrosion resistance characteristics. Large ferrite magnitudes decrease the hardness and the transformation temperature, particularly in alloy grades with 80 percent ferrite content.

The duplex stainless steel grades offer good fatigue properties as a result of their enhanced yield strengths.

Corrosion Resistance

The excellent corrosion resistance provided by the high functionality stainless steels is not only because of their alloy percentage but also of the synergistic influence associated with the interaction of large chromium and other compositional agents. For instance, small percentage of nickel in a chromium ferritic steel will excellently increase its resistance in the reducing media. Molybdenum is an essential element in providing resistance to chloride pitting corrosion with increase in the chromium percentage. There are significant variations in the steel grades considering the conditions and various kinds of corrosion.

The corrosion resistance provided by high functional stainless steels in sulfuric acid solutions is recognized by the oxidizing potential of the particular sulfuric acid condition. The availability of chloride or other halide ions can cause pitting attack when a specific stainless steel is anticipated to show an adequate performance. Alloy 825 is a standard stainless steel that is suitable for use in any content range of sulfuric acid at temperatures lower than 60 oC or 140 oF.

The high performance stainless steels are employed in applications in reducing media, sulphurous acid, phosphoric acid, hydrochloric acid, hydrofluoric acid, nitric acid, acetic acid, fatty acid, sodium hydroxide and various alkaline containing oxidizing environments. They are also used in natural waters and brines, oxidizing halide conditions, chlorinated cooling waters and bleaching solutions, flue gas etc.

Applications

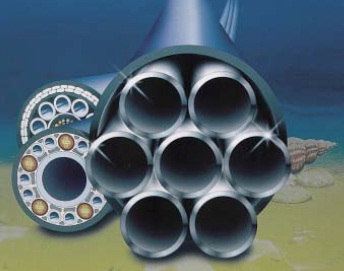

The high functionality stainless steels offer a wide variety in corrosion resistance, physical and mechanical properties. They are used in thousands of applications in the several areas of process, energy, paper and other industrial sectors. Heanjia Super-Metals produces high functionality steels in the all forms such as wire, sheet, strip, pipe, tubing, rod, bar, plate, flanges etc. These are the best and economical solution to several demanding industrial application challenges.